The Importance of Construction Site Safety & Key Info You Need to Know

As key personnel on a construction site, it’s crucial to prioritise and maintain safety at all times. You should have made yourself familiar with the HSE’s official guidance, but we’ve laid out the key pieces of information on construction site safety to give you a refresher.

Keeping a construction site productive means keeping it safe, but ensuring the job you're running complies with safety regulations and stays on schedule is a balancing act.

The HSE's guidelines provide a great starting point, but it's ultimately your (or your site manager's) responsibility to ensure everyone on site is aware of and following safety protocols.

10 Construction Site Safety Rules

- Always wear PPE

- Get your induction

- Be tidy

- Act safe

- Follow signs

- Do not enter

- Report problems

- Don't tamper with safety equipment

- Use the right equipment

- If in doubt, ask!

As a foreman or project manager, enforcing these 10 essential safety rules is key to maintaining safety on construction sites. These rules are designed to reduce risks, protect workers, and create an organised, efficient work environment.

Following them isn’t just about meeting legal requirements – it’s about protecting the safety and well-being of everyone on-site.

Start by educating your team. Regular safety inductions and toolbox talks help workers understand the rules and why they matter.

Lead by example; your dedication to safety will influence the whole team. Use clear signage and frequent reminders to keep safety top of mind.

Regular inspections can also help identify hazards and ensure everyone is staying compliant.

By prioritising these safety measures, you build a culture where everyone plays a part in keeping the site secure. This not only reduces accidents, but also improves morale and productivity.

What are the Top 5 Hazards on a Construction Site?

There are numerous hazards present on a construction site, which would (and should) have been identified as part of the risk assessment process.

The specifics will vary from site to site, depending on the nature of the project and the surrounding environment. However, there are some common hazards that can be found on almost any construction site.

Falls From Height

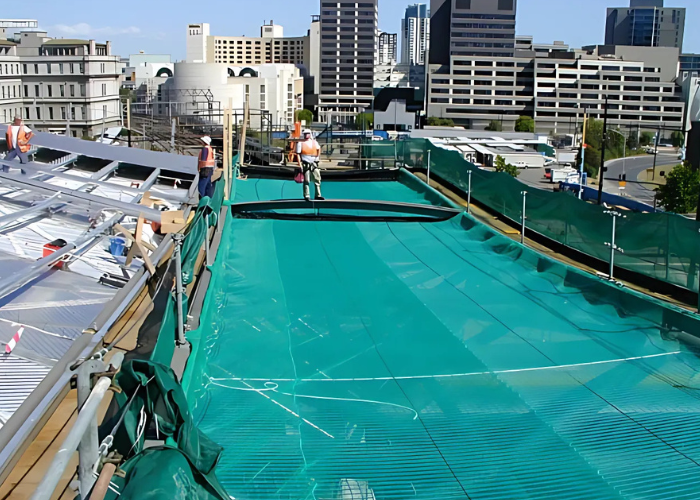

Falls from height are a leading cause of injuries and deaths on construction sites. Workers often operate on scaffolding, ladders, or other elevated surfaces, which pose serious risks if safeguards are lacking.

Under UK law, the Work at Height Regulations 2005 require employers and workers to follow safety rules for any work where a fall could cause injury. Employers must assess risks and provide safety measures, such as harnesses, guardrails, and well-maintained scaffolding.

The regulations prioritise avoiding work at height whenever possible. If unavoidable, risks should be reduced with collective prevention measures (e.g., edge protection) before relying on personal protective equipment (PPE).

Preventing falls from height requires a proactive approach, prioritising safety at every stage of work.

- Install Fall Arrest Systems: Equip worksites with fall arrest safety netting, harness systems, and anchored lifelines to protect workers in the event of a fall.

- Conduct Risk Assessments: Identify potential hazards and implement controls before work begins.

- Use Stable and Well-Maintained Equipment: Ensure all ladders, scaffolding, and platforms are stable, secure, and inspected regularly to prevent equipment failures.

- Provide Edge Protection: Install guardrails, toe boards, or edge barriers to reduce the risk of slips or falls from unprotected edges.

- Deliver Proper Training: Train all workers on the safe use of equipment, fall prevention techniques, and emergency procedures to enhance workplace safety awareness.

- Monitor Weather Conditions: Avoid working at height during adverse weather conditions, such as strong winds or heavy rain, which can increase the risk of accidents.

Order Compliant Fall Arrest Netting Online

Moving Machinery

Moving machinery presents significant safety risks on construction sites, including crushing, entanglement, and collision hazards.

Workers can be injured by unguarded parts, unexpected movements, or poor visibility around equipment. To mitigate these risks, UK laws, such as the Provision and Use of Work Equipment Regulations 1998 (PUWER), require that machinery is suitable for use, maintained in safe condition, and operated by adequately trained personnel.

The Health and Safety at Work Act 1974 also mandates employers to ensure the safety of workers by implementing safeguards, proper training, and clear procedures when using heavy machinery on-site.

Order Safety Barrier Netting for Your Site

Hazardous Materials

Hazardous materials pose significant risks on construction sites, including health issues, fire hazards, and environmental contamination. Improper handling can lead to serious accidents or long-term exposure effects.

Laws such as the Control of Substances Hazardous to Health (COSHH) Regulations in the UK mandate proper assessment, storage, and disposal of such materials.

Compliance with these laws is essential to minimise risks, safeguard worker health, and prevent legal consequences.

Electrical Risks

Electrical risks on construction sites include shocks, electrocution, and fires resulting from exposed wires, faulty equipment, or improper use of electrical systems.

Workers face significant hazards if equipment is not correctly maintained or if live parts are improperly isolated.

The Electricity at Work Regulations 1989 mandates safe practices for construction-related electrical systems, requiring that circuits, tools, and installations are regularly inspected and maintained.

Proper grounding, use of Residual Current Devices (RCDs), and restricting access to qualified personnel help mitigate these dangers.

Order Security Nets & Fencing Today

Slips or Trips

Slips or trips on construction sites can lead to serious injuries, often caused by uneven surfaces, trailing cables, or spillages.

Poor site organisation and inadequate lighting can exacerbate these risks, making hazards less visible.

To mitigate these dangers, it is important to maintain clear walkways, promptly clean up spills, and secure loose cables.

Additionally, proper signage and regular inspections can help identify and address potential hazards.

Are Construction Workers Responsible for Maintaining Site Safety?

Construction workers share responsibility for site safety by following protocols, using equipment correctly, reporting hazards, and adhering to training.

However, employers must provide training and PPE, and enforce safety measures to ensure a secure and compliant work environment.

How to Comply With Health & Safety in the Construction Industry

To make sure your site complies with the latest health and safety requirements, here are some key steps to follow:

1. Use the Right Equipment

Using the right equipment for your specific construction project and site location is crucial for ensuring both safety and efficiency.

Different types of construction work require specialised tools and machinery designed for the task at hand, as using improper equipment can lead to accidents, damaged materials, or project delays.

Site conditions such as uneven terrain, confined spaces, or extreme weather may also necessitate equipment tailored to those challenges.

By selecting the correct tools and machinery, you reduce the risk of injuries, maintain compliance with health and safety regulations, and ensure the quality of the work being carried out.

2. Install Compliant Industrial Netting

Order Regulation Industrial Netting

Installing regulation-compliant industrial netting is crucial for maintaining a safe and secure work environment. This type of netting, including load restraint nets and hoist netting, provides a dependable barrier that helps to protect areas, equipment, and materials from potential hazards.

For example, debris netting can prevent debris from falling in high-risk zones, safeguarding workers and minimising damage to valuable assets. Or, investing in anti-litter netting can help keep your site compliant with environmental safety regulations.

We provide a professional installation service through our sister company, HuckTek. Our experienced installation team will install your safety netting to maintain compliance with legal regulations to get your site up and running quickly and efficiently.

3. Install Compliant Safety Netting

View Our Full Range of Safety Netting

Installing compliant safety netting is crucial for ensuring the safety of workers and the public on construction sites. It acts as a protective barrier, preventing debris or materials from falling and causing potential harm.

This is particularly important in high-risk environments where construction activity occurs at height or in close proximity to pedestrian areas, such as fall arrest safety nets or skylight safety netting.

It's also important to consider that compliant safety netting helps mitigate financial and reputational risks by reducing the likelihood of accidents or damage from falling debris with our scaffolding netting.

Our safety netting is also subject to annual strength testing in our South West-based factory to ensure your installed netting remains structurally sound and strong enough for its intended use.

4. Maintain Safety Netting

Regular maintenance of your safety netting is essential to ensure its continued effectiveness over time.

Once installed, safety netting can be exposed to various environmental factors, including UV degradation, abrasive wear, and general ageing.

By conducting routine inspections for tears, holes, or any visible damage, you can address potential issues early and reduce the likelihood of failures that might compromise safety.

Annual strength testing is another key step, as it allows you to know the netting is maintaining its structural integrity and strength, adhering to safety standards.

We offer safety net testing for all nets, including those manufactured by other companies. Our routine testing ensures the strength of your safety net still meets the legal requirements for its use. Our strength tests can help you replace worn netting before it reaches failure.

If the netting no longer meets these standards or shows signs of significant wear, timely replacement is crucial to prevent accidents and maintain a safe working environment.

Proper upkeep of your safety netting protects everyone on-site and maintains compliance with industry regulations.

Risks of Not Following Site Safety Rules

Failing to adhere to construction site safety rules can lead to severe consequences, including injuries, fatalities, and long-term health issues for workers and visitors.

From a professional and organisational standpoint, neglecting construction health and safety regulations can damage a company’s reputation, reduce staff morale, and lead to higher employee turnover.

Poor safety practices may also result in financial penalties, increased insurance premiums, and civil liability costs in the event of a claim from injured parties.

Legally, non-compliance with site safety standards can have serious consequences under UK law.

Keep Your Construction Site Up to Code With Huck Nets

At Huck Nets, we offer a vast range of industrial netting and safety netting designed to help keep your construction site up to code.

Our products are manufactured to meet the highest safety standards, ensuring reliable protection for workers and equipment on-site. From debris nets and scaffolding nets to safety netting for fall protection, our solutions cater to various construction site needs.

By installing compliant netting, you can mitigate risks, enhance site safety, and meet legal health and safety requirements effortlessly.

Trust Huck Nets to provide durable and dependable netting systems tailored to your project's specifications. Shop our full range online today.

FAQs

What Safety Measures Should Be Taken on a Construction Site?

Ensure all workers wear appropriate personal protective equipment (PPE), maintain clean and organised workspaces, install proper safety netting and barriers, conduct regular risk assessments, and provide adequate training to minimise accidents and ensure compliance with legal safety standards.

How Often Should Safety Netting Be Checked for Strength?

Safety netting should be checked regularly. Installation should be checked before each use to ensure it maintains its strength and functionality. Manufacturer inspections should take place every 12 months to guarantee continued efficacy.

What is Full PPE for a Construction Site?

Full PPE for a construction site typically includes a hard hat, high-visibility clothing, steel-toe boots, gloves, safety goggles, and hearing protection, ensuring workers are safeguarded against potential hazards present in the construction environment.